Novel eco-friendly conductive ink designed to transform flexible electronics manufacturing

As it is water-based, this ink is more sustainable, eco-friendly, and significantly reduces the environmental impact of existing solutions.

English version: Diana Taborda

Manuel Reis Carneiro, CMU Portugal Dual Degree Ph.D. student in Electrical and Computer Engineering at the Faculty of Sciences and Technology of the University of Coimbra (FCTUC) and Carnegie Mellon University (CMU), has developed a water-based conductive ink for the manufacturing of flexible electronic circuits, free of organic solvents, which are both polluting and harmful to the environment. The method has just been published in the scientific journal Advanced Science.

As it is water-based, this ink is more sustainable, environmentally friendly and significantly reduces the environmental impact of standard methods. Possible applications include health monitoring stickers or monitoring the quality of food products.

Manuel Reis Carneiro is a researcher at the Institute of Systems and Robotics (ISR)of the University of Coimbra, and is a member of a research team led by Mahmoud Tavakoli, who already has extensive experience in the development of flexible electronic circuits. Producing these circuits smoothly, quickly and affordably has been one of the main goals of the Coimbra team, which now takes a new step in achieving its goal by developing a sustainable and environmentally friendly ink.

Manuel Carneiro explains that "The use of a water-based ink for printing and producing flexible and soft electronic circuits electronic circuits has numerous advantages. On the one hand, it significantly reduces the environmental production impact because it doesn't use toxic materials. On the other hand, it simplifies the recycling and subsequent reuse of the circuits, which was previously a complex process. With this method, all we have to do is soak the chip-integrated soft circuits in alcohol, which leads to the separation of the components and the metal particles and they are ready to be recycled and reused".

Another great advantage is that this ink, unlike others, does not have to be refrigerated; it can be kept at room temperature for about a month, which facilitates its preservation, reduces the carbon footprint and lowers maintenance costs.

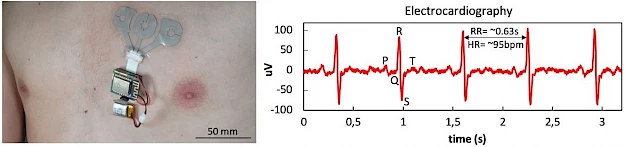

These flexible circuits currently have many applications, particularly in the health sector such as biomonitoring sensors and patches that can record patient health data, namely muscle activity, respiration rate, body temperature, heart rate, brain activity or even emotions. The majority of medical devices used in healthcare, such as electrodes for electrophysiology, are single-use and discarded after one use. This new ink allows for simple and inexpensive recycling, having a great impact on the reuse of monitoring patches, significantly reducing the electronic waste - also known as e-waste - generated by single-use products.

The food industry is another sector that can benefit from this finding by integrating it into the next generation of smart packaging. The team tested the application of this new ink on electronic printed labels applied to smart packages, which record the storage temperature of perishable items and warns consumers about unsafe storage conditions that can lead to product contamination.

The ISR-FCTUC team has been making significant progress in the area of flexible electronic circuit manufacturing, in order to enable a cost-effective production on a large scale. These circuits can already be created using a traditional 3D printer, and last year the team presented an alternative for integrating solid-state microchips into flexible materials and circuits based on elastic polymers.

The production of water-based conductive inks and reducing the environmental impact of electronic waste is another step towards the team's goals. "As the world becomes increasingly dependent on electronic devices, it is crucial to recognise and address the environmental challenges posed by the new waste created. We thus aim to develop innovative electronic systems based on flexible electronics, with various cutting-edge functionalities and applications in both medicine and industry, but always taking into account sustainability, resource efficiency and minimal environmental impact," says Carneiro.

The scientific article “Recyclable Thin-Film Soft Electronics for Smart Packaging and E-Skins” is available here.